Industrial processes depend on reliable fluid handling systems to keep production moving efficiently and safely. As materials become more complex and performance expectations increase, industries require pumping solutions that can handle diverse challenges without compromising consistency or control. This is where progressive cavity pumps have earned their reputation as indispensable tools across many sectors. Their ability to deliver steady flow, manage difficult materials, and support precision processes explains why they continue to play such important roles in modern operations.

Understanding the Core Function of Progressive Cavity Pumps

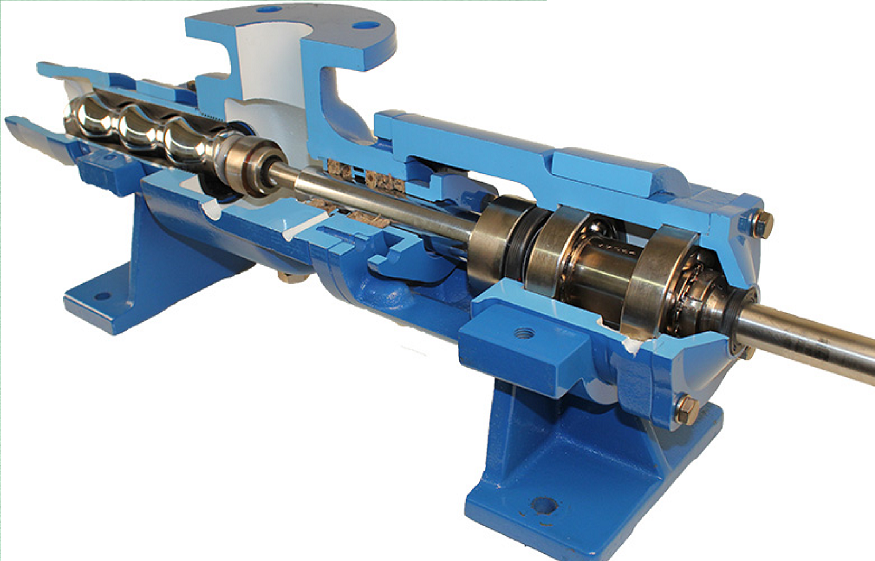

Progressive cavity pumps operate using a rotating helical rotor within a stationary stator, forming sealed cavities that move fluid smoothly from inlet to outlet. This design allows for continuous, non pulsating flow, even under varying pressure conditions.

Unlike high speed pumping systems that rely on turbulence, progressive cavity pumps move fluids gently and predictably. This makes them ideal for applications that demand accuracy, stability, and material integrity. Their operating principle is simple yet highly effective, contributing to their widespread use.

Handling Challenging Materials With Ease

Many industrial fluids are not easy to move. Thick slurries, viscous pastes, abrasive mixtures, and shear sensitive materials can quickly damage or overwhelm traditional pumping systems. Progressive cavity pumps are specifically suited for these challenges.

Because they operate at low speeds and create minimal shear, they can move difficult materials without altering their composition. This capability makes them valuable in industries such as wastewater treatment, chemical processing, mining, and food production, where maintaining material characteristics is essential.

Consistent Flow for Process Stability

Consistency is a cornerstone of efficient industrial processes. Fluctuations in flow can disrupt production, reduce quality, and increase waste. Progressive cavity pumps deliver steady, metered flow regardless of pressure changes, which supports stable and predictable operations.

This reliability is especially important in applications that involve dosing, metering, or transferring materials between stages. By maintaining precise flow rates, these pumps help operators achieve tighter control over processes and improve overall efficiency.

Supporting Quality Driven Industries

Industries that prioritize precision and performance rely on quality pumps to maintain standards and reduce operational risks. Progressive cavity pumps meet these expectations by combining durability with accuracy.

Their design minimizes wear caused by turbulence and vibration, contributing to longer service life and dependable performance. When industries invest in pumping solutions, they often look for systems that deliver consistent results over time, and progressive cavity pumps are frequently chosen for this reason.

Performance Under Pressure and Variable Conditions

Industrial environments are rarely static. Pressure levels, temperatures, and material properties can change throughout a process. Progressive cavity pumps are well suited to these variable conditions, as their flow rate remains proportional to rotational speed rather than pressure.

This ability to perform consistently under pressure makes them valuable in systems where back pressure fluctuates or where long piping runs are involved. Operators can rely on predictable output without constant adjustments, simplifying system management.

Energy Efficiency and Operational Control

Energy efficiency has become a major focus in modern industry. Equipment that operates smoothly at lower speeds often consumes less energy and generates less heat. Progressive cavity pumps align well with these goals.

Their controlled movement reduces energy losses associated with turbulence and cavitation. In addition, their precise control allows operators to match pump performance closely to process requirements, avoiding unnecessary power consumption and improving overall system efficiency.

Reduced Maintenance and Downtime

Downtime is costly in any industrial setting. Equipment that requires frequent repairs or replacements can disrupt operations and increase expenses. Progressive cavity pumps are designed with maintenance in mind, often allowing key components to be serviced without extensive disassembly.

Because these pumps handle materials gently and reduce internal stress, wear rates can be lower compared to more aggressive pumping systems. This reliability contributes to fewer unexpected failures and more predictable maintenance schedules.

Versatility Across Multiple Industries

One of the strongest reasons progressive cavity pumps play such important roles is their versatility. They are used across a wide range of industries, including water treatment, oil and gas, agriculture, construction, and manufacturing.

Their adaptability allows them to handle everything from thin liquids to highly viscous substances with solid content. This flexibility reduces the need for multiple specialized pumping systems, simplifying equipment selection and system design.

Precision in Dosing and Metering Applications

Accurate dosing is critical in many processes, particularly those involving chemicals, additives, or controlled mixtures. Progressive cavity pumps excel in these applications due to their linear flow characteristics.

Each rotation moves a fixed volume of fluid, making it easier to achieve precise dosing. This level of control improves product quality, reduces waste, and enhances safety in sensitive operations.

Meeting Modern Industry Expectations

As industries evolve, expectations around reliability, efficiency, and sustainability continue to rise. Progressive cavity pumps meet these demands by offering long term performance, controlled operation, and compatibility with modern automation systems.

Their ability to integrate with variable speed drives and monitoring technologies makes them suitable for advanced industrial environments. This adaptability ensures they remain relevant as processes become more automated and data driven.

Why Progressive Cavity Pumps Continue to Matter

The ongoing demand for dependable and adaptable pumping solutions highlights the importance of progressive cavity pumps in today’s industrial landscape. Their unique design supports consistent flow, gentle material handling, and reliable performance across a wide range of applications.

When industries seek quality pumps that deliver precision, durability, and operational stability, progressive cavity pumps consistently stand out. Their continued use across diverse sectors demonstrates why they play such critical roles and why they will remain essential as industrial processes continue to advance.

How Long Does It Take to Set Up a Business in the UAE?

How Long Does It Take to Set Up a Business in the UAE?  Why Progressive Cavity Pumps Play a Critical Role in Modern Industrial Operations

Why Progressive Cavity Pumps Play a Critical Role in Modern Industrial Operations  How to Get Instant Personal Loan Without Income Proof

How to Get Instant Personal Loan Without Income Proof  Difference Between a Savings Account & Current Account

Difference Between a Savings Account & Current Account